HeavyBOS

- HeavyBOS

- Feature & Benefits

- Product Range

- Technical

- Dimensions

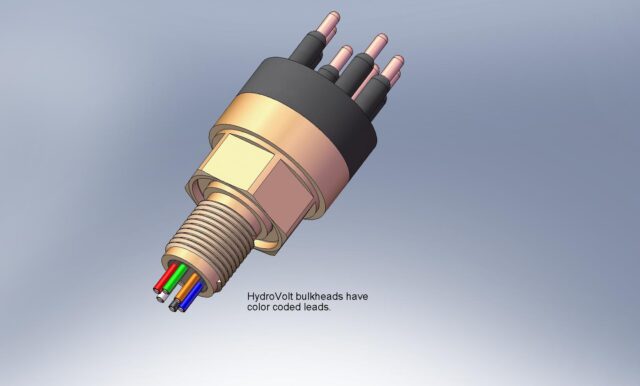

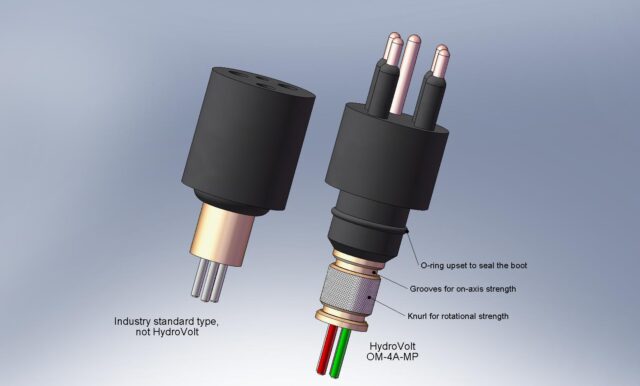

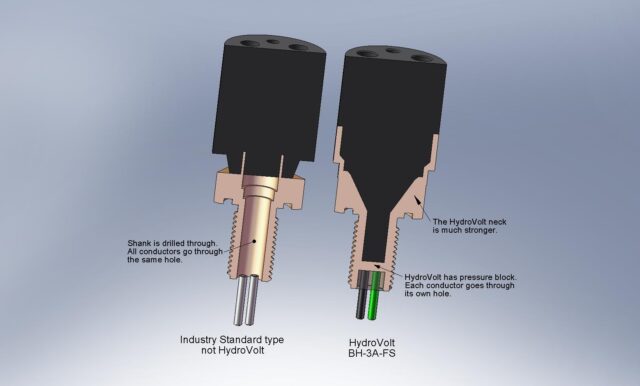

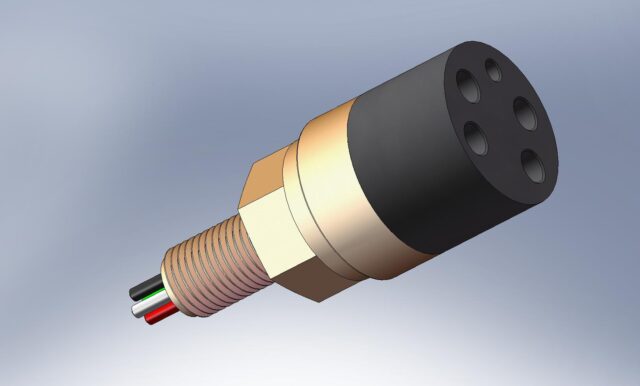

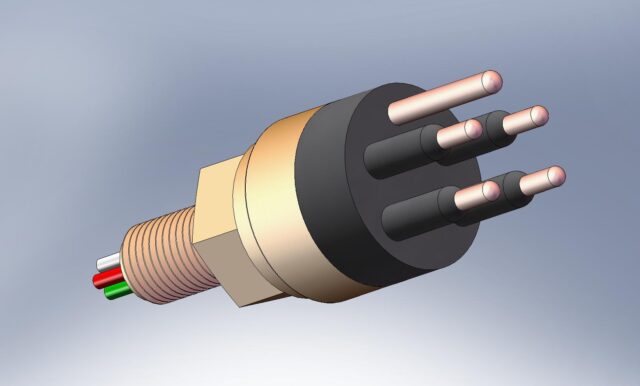

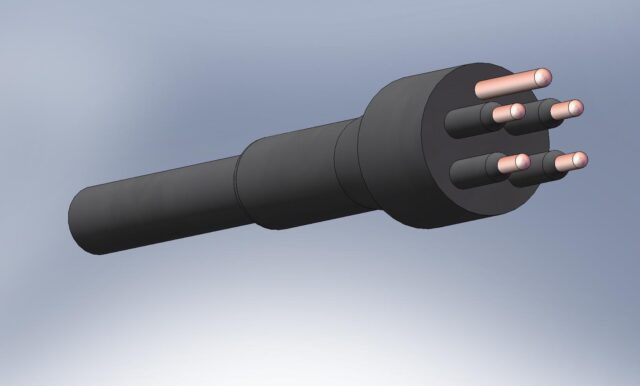

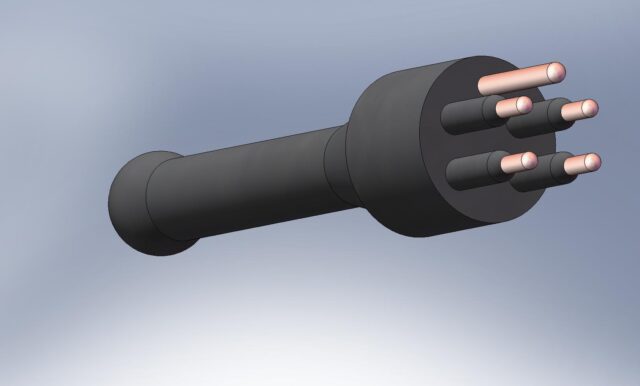

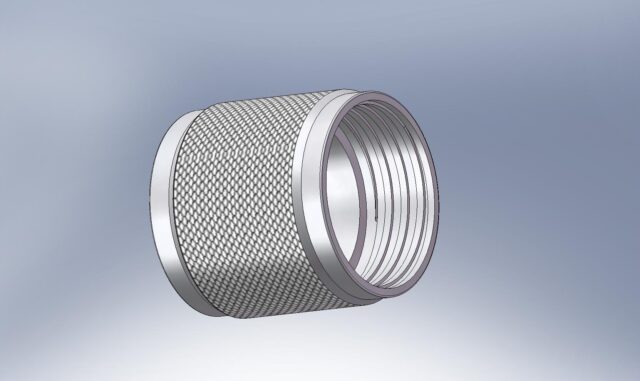

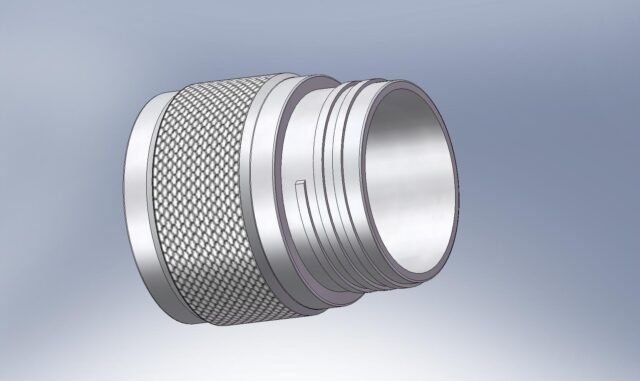

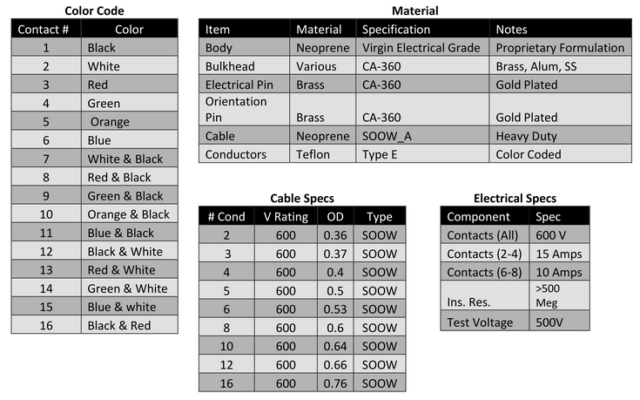

Our HeavyBOS connectors are designed for maximum ruggedness. These are heavy connectors with thick cross sections. They are best for fixed locations where weight is not an issue, but ruggedness is necessary.

The BOS acronym started out as an internal light hearted name that meant bulkhead-on-steroids, due to their massively heavy and strong shells. Eventually customers started calling them BOS as well, so we stuck with that name.

HeavyBOS Product Range

WORLDWIDE

Distribution

We work with a network of trusted distributors to ensure our underwater electrical connectors are available to customers around the world.