Products

Products

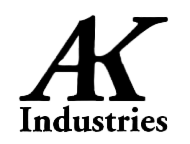

Our HeavyBOS connectors are designed for maximum ruggedness. These are heavy connectors with thick cross sections. They are best for fixed locations where weight is not an issue, but ruggedness is necessary.

The BOS acronym started out as an internal light hearted name that meant bulkhead-on-steroids, due to their massively heavy and strong shells. Eventually customers started calling them BOS as well, so we stuck with that name.

Our LiteBOS connectors are designed to be rugged, but with the constraint of being as light as is practicable.These are excellent where weight is an issue such as ROVs and AUVs. They are also a bit smaller than their big brothers due to less massive cross sections.

The LiteBOS connectors were derived from our HeavyBOS connectors that customers love, but couldn’t deal with the weight. They asked us for something tough, but much lighter. They liked some of the features of the HeavyBOS, such as snug-fitting locking sleeves that help the inline cables deal with off-axis bending.

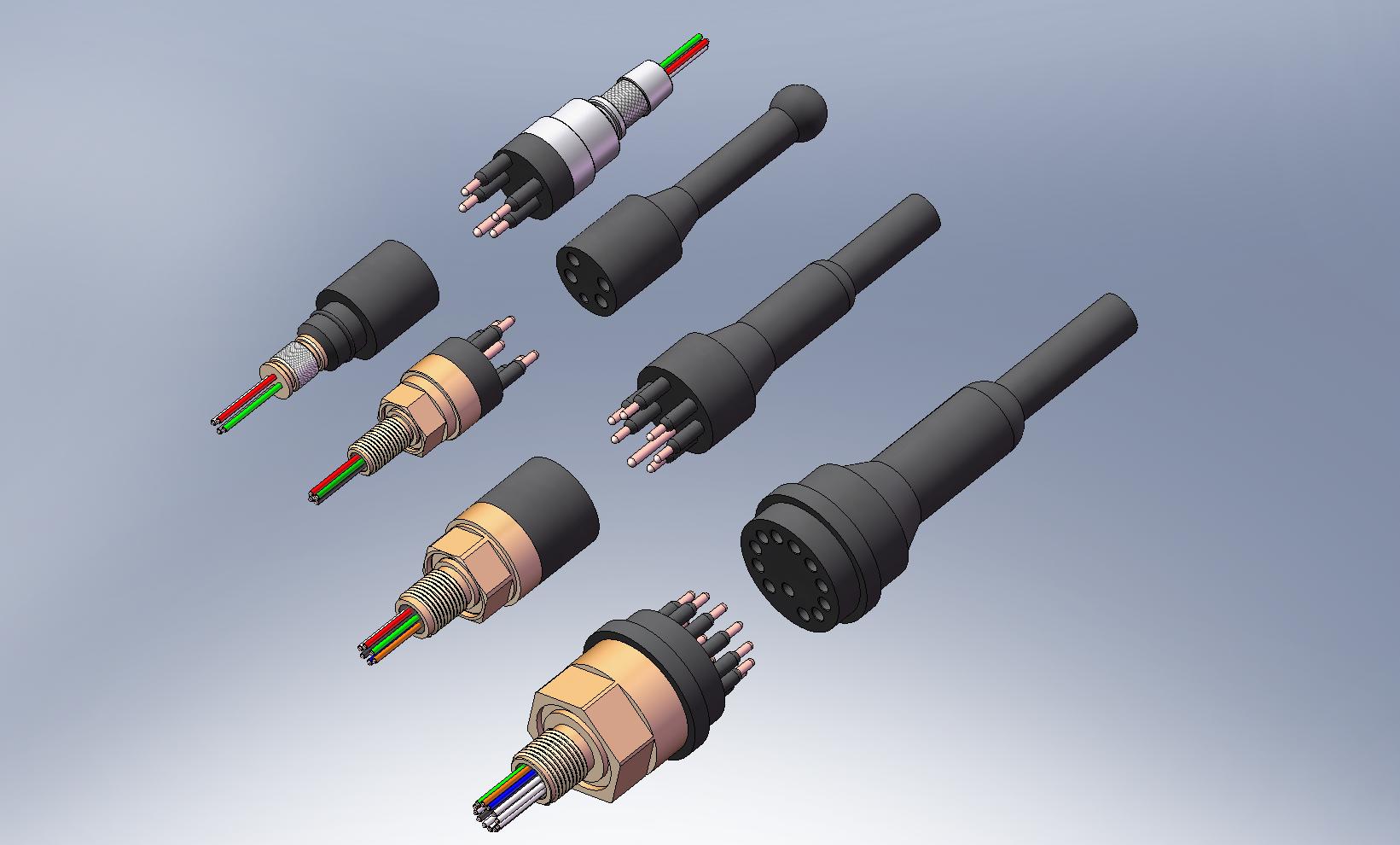

Our Nano connectors are very small and dense. They can be very small because there is no metal shell. They are molded from a tough dielectric elastomer. Since there is no external metal shell, they are substantially more compact.

Our penetrators have a unique “cage shell” that protects the water blocking inside the penetrator

We make a variety of breakouts, and we can make anything that a customer might need.

We are expert at making custom connectors and penetrators for unusual or special applications. We make our own mold tooling in house. We work with customers to define their requirements and build custom tooling to do just that.

WORLDWIDE

Distribution

We work with a network of trusted distributors to ensure our underwater electrical connectors are available to customers around the world.