Underwater Electrical Connectors

B - size male locking sleeves have a second groove. That is because the female bulkhead in the B - size is approximately 0.25" longer than the inline. The reason is due to the contact pattern bolt circle is close to the outer edge. That forced the sockets forward lest they be to close to the shell.

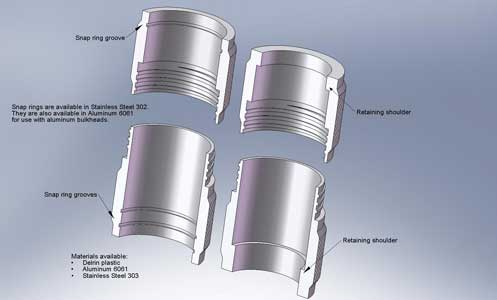

B - size locking sleeves are also available with a shoulder instead of the grooves. Unlike grooves, we can only put in one shoulder. Since most users require the bulkhead to be male and the inlines to be female, we set the shoulder accordingly (that configuration would use the forward groove in the male locking sleeve). If your bulkhead is a female and therefore inline male you must use the traditional snap ring locking sleeves.

Shoulder style locking sleeves are stronger and have the advantage of not introducing an additional metal part because t hey do not require a snap ring. However, they cannot be installed after a bulkhead has been installed, nor can they be installed into a double-ended cable assembly (unless we do it before we make the second end).

If you buy cable assemblies with locking sleeves, we recommend that you specify shoulder style locking sleeves with your order because they must be installed during manufacture. Then, if there is damage to the locking sleeve, a groove type locking sleeve can be installed anytime later.

A note about Stainless Steel (SS)

Series 300 stainless steels are the highest quality and most corrosion resistant of the stainless steels. They are much more corrosion resistant than the 400 series, for example: Why do we use 303 on the locking sleeves and 302 on the snap rings? Type 303 is easier to machine than other 300 series SS. There is a lot of machining to make a locking sleeve. However, 302 can be work hardened to have better spring properties needed for snap rings.

Locking sleeves are not necessary for the functionality of HydroVolt connectors. However, some customers prefer the assurance that the connectors will not become disengaged by pulling on a cable.

Locking sleeves are available in several different materials. Delrin, Aluminum 6061, and Stainless Steel 303. We manufacture our own locking sleeves on a Mori Seiki turning center and so we can easily make them with other materials specified by the customer.

Standard locking sleeves are available with the traditional snap ring groove. They are very convenient for adding a locking sleeve after a bulkhead has been installed, or anytime on a cable assembly. We have snap rings made from Stainless Steel 302, and also Aluminum 6061 (mostly for use with aluminum bulkheads). Aluminum snap rings are much better in contact with aluminum bulkheads for galvanic corrosion reasons. Please see the Technical Notes page for more information about galvanic corrosion.

HydroVolt: B - Size, 1.25" (32 mm) dia - Locking Sleeves